With the anticipation of their Model 3 release, Tesla has confirmed that production of the new Model 3 battery has commenced over the weekend.

These new battery cells are the cost efficiencies that are rumored to allow Tesla achieve the Model 3’s $35,000 starting price tag.

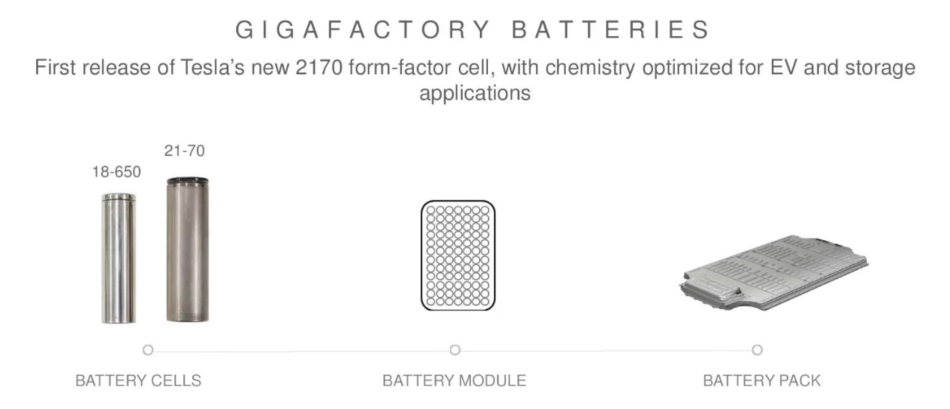

Although Tesla’s new 2170 format battery cells began production in January, those cells were using Nickel Manganese Cobalt Oxide (NMC). This chemistry was more developed for stationary energy storage items such as Tesla’s Powerpack and Powerwall.

For its vehicles, Tesla has been using Nickel Cobalt Aluminum Oxide (NCA) chemistry that has been optimized for use in electric vehicles. While the company confirmed that different batteries will be used in the Tesla Model 3, it was unconfirmed whether these batteries would still operate by NCA chemistry.

At a Keynote presentation at Midwest Renewable Energy Association’s 28th Annual Energy Fair, Chief Technology Officer, JB Straubel confirmed that Tesla has commenced production of these new battery cells. Straubel continued, that they were currently beginning the production lines for the new Model 3 battery cells, and are prepared to increase production if necessary.

In order to use the 2170 battery cells in the Model 3, Tesla has designed new pack architecture and battery modules. While Tesla is in charge of manufacturing the modules and overall battery packs, the cells are manufactured by Panasonic. Everything is done in Nevada under Tesla’s Gigafactory 1 facility.

Despite Panasonic and Tesla’s silence on the new battery cell technology, Tesla CEO Elon Mask has openly boasted about the new innovation. In his words, it has the “highest energy density cell in the world and also the cheapest”.

With the new battery cells, Tesla has been aiming to achieve cost reductions as much as 35%. Although there was talk of eventually implementing the same technology into both the Model S and Model X, Musk added today that no changes to cell formats for the Model S or X are currently planned.

With plans for Gigafactory 1 to reach 50 GWh of energy capacity in the form of battery packs by the end of 2018, this represents a production of 500,000 cars, and many more Powerwalls and Powerpacks.

Not only will the new cells be more cost efficient, but may also provide additional durability as well. Jeff Dahn, a Tesla Battery researcher has hinted at significant breakthroughs that should improve the lifecycle of Lithium-ion batteries.

Although the timeline of the new breakthroughs are still unclear, the start of Model 3 Battery Cell signals a considerable milestone in the production and anticipated launch of the vehicle.

With a delivery event planned for the end of the month, Tesla plans to ship battery packs produced in Nevada to Tesla’s Fremont factory. It is here where the production of the Model 3 will commence.

Featured Image: twitter