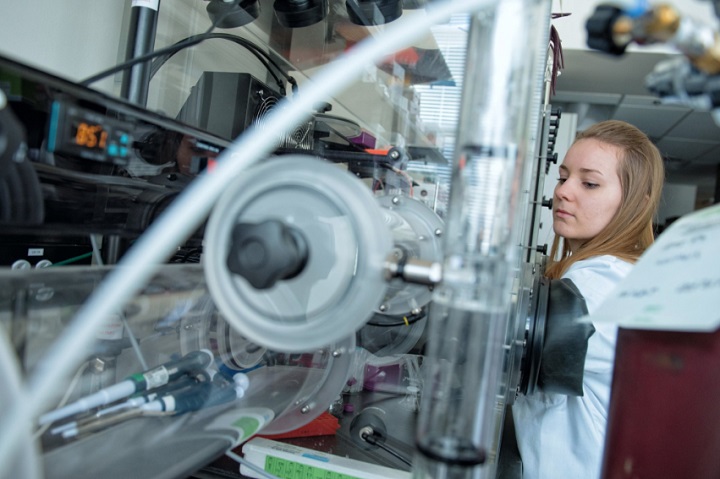

It has been reported that a team of researchers has created a new process which could drastically improve how bioreactors break down organic material into methane gas. The process was partially developed at the University of British Columbia.

The researchers, which include Cigdem Eskicioglu, an associate professor of engineering at UBC’s Okanagan Campus, say that the method for pretreating biomass has the ability to increase methane output in bioreactors by up to 172% and could cause cheaper and safer biofuels. Eskicioglu is currently working on a number of collaborators in Europe and Australia on the project.

“The potential to more efficiently harness the energy from forestry waste products like tree bark can open a world of new opportunities.” She added, “Our new fermentation process would be relatively easy to implement on site and because the bioreactors can be smaller, the costs can be kept low.”

For those unaware, methane is the main component of natural gas and is commonly used to create electricity in the power sector. Aside from extracting it from gas fields, methane can be produced by fermenting organic material.

The new process – known as hydrothermal pre treatment – involves treating organic material with carbon dioxide at high temperatures and pressures before the mixture enters the fermentation stage. The new process is significant as it is unlike conventional methods for pretreating biomass. Why? Because the new process does not require or produce any toxic chemicals, thus making the methane production safer.

According to the team of researchers, the process ranges in effectiveness depending on the type of biomass that is used. Also, the refractory materials, like pine residues, generate the best results. For example, Douglas fir bark proved to produce methane 172% faster than previous attempts.

“We still have some work to do to move it to an industrial scale, but our results so far are very promising,” Eskicioglu added.

Featured Image: twitter